Products > HP supply units > Gas compressor U11

Parameters:

Pressure : up to 1500 MPa

Pressure medium : Helium, Argon, Nitrogen

Gas supply pressure min. : 10 MPa

Essential Features :

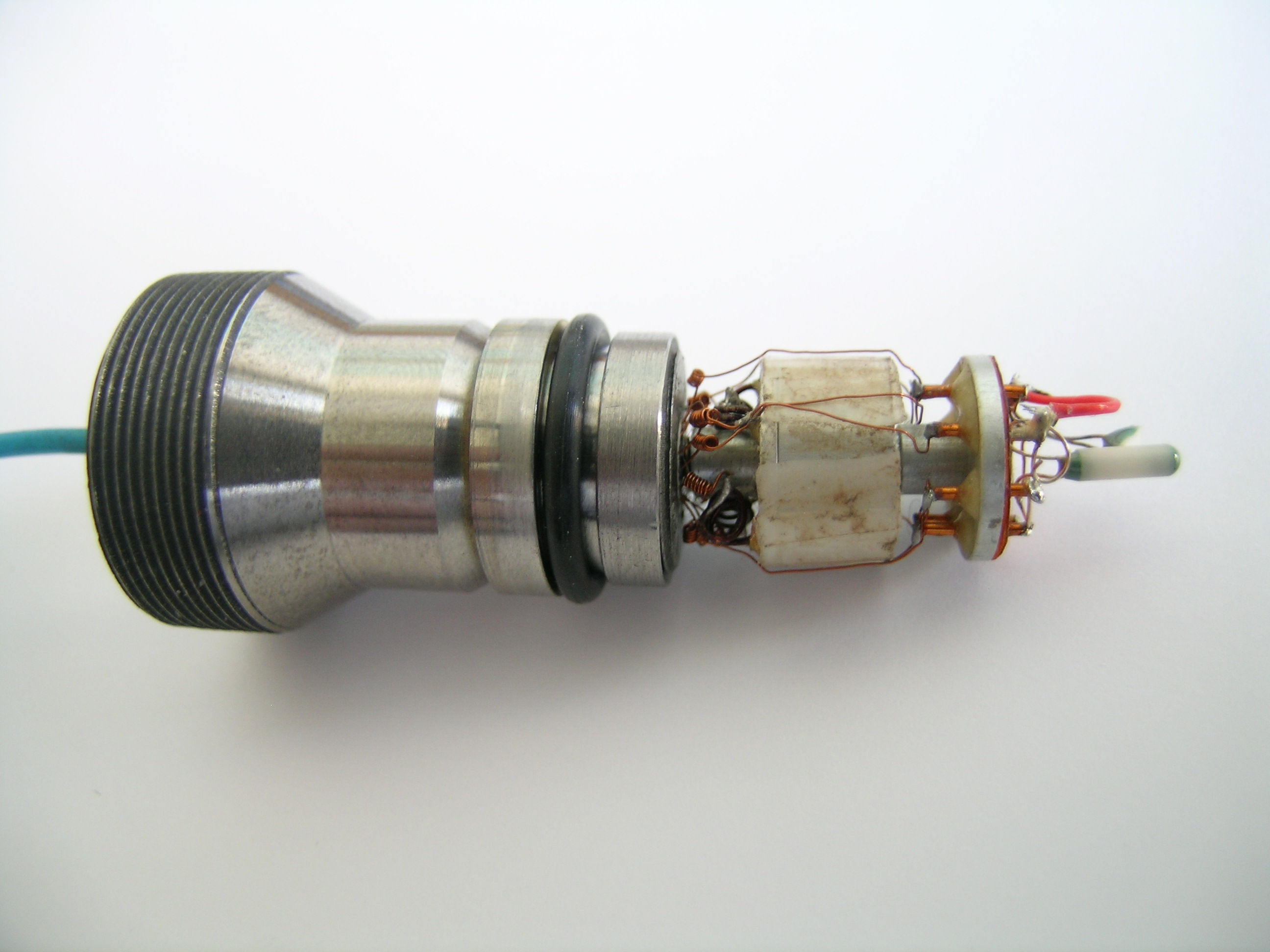

Our Gas Compressor U11 has been developed to generate high pressure in gases using hydraulically driven multiple compression stages (piston-cylinder type). Compressors are operated using manual valves. Two pressures in the system are monitored and displayed: primary oil pressure as well as high gas pressure. Gas pressure is measured using Manganin pressure gauge located in the last compression stage (Basic and Technological compressor) or pressure transducer (Customized compressors). Speed of compression is controlled using potentiometer (frequency inverter). Various high pressure measuring cells can be connected to the compressor using flexible capillary tube. We offer three types of U11 compressors.

| Type | Working Pressure [MPa] | Compression stages | Last stage volume [mL] | Last stage pressure range [MPa] | Weight [kg] |

|---|---|---|---|---|---|

| Basic | 1500 | 3 | 15.4 | 330…1500 | 550 |

| Technological | 1300 | 3 | 75 | 330…1300 | 700 |

| Customized | 600 | 2 | 67 | 70…600 | 350 |

| Customized | 500 | 1 | 24 | 15…500 | 300 |

| Customized | 400 | 2 | 102 | 70…400 | 350 |

In U11-Basic type high pressure experiments can be carried out also directly in the high pressure chamber of the final stage of the compressor.

For sophisticated measurements (e.g. dilatometric) with fine pressure control for temperature/pressure sweeps, the compressor U11-Customized can be equipped with special Micropump MP Series. In such configuration working pressure is limited up to 300 MPa.